When you're selecting fabric for your next project, you'll find Oxford cloth stands apart from standard weaves. This distinct textile combines thicker and thinner yarns in a basket-weave pattern, creating its characteristic texture and durability. You'll encounter Oxford fabric in various forms, from traditional cotton dress shirts to water-resistant outdoor gear. Understanding its types, construction methods, and specific applications will help you determine if it's the right material for your needs.

Key Takeaways

- Oxford fabric is a durable basket-weave textile made by interlacing thick and thin yarns in a crosswise pattern.

- Four main types exist: Plain Oxford, Pinpoint Oxford, Oxford Nylon, and Royal Oxford, each with distinct textures and uses.

- The fabric's 2x1 weave construction creates superior strength, breathability, and resistance to wear and tear.

- Common applications include dress shirts, casual wear, uniforms, upholstery, and outdoor gear like tents and backpacks.

- Oxford fabric can be made from cotton, polyester, or blends, with specialized coatings available for water resistance.

What is Oxford Fabric?

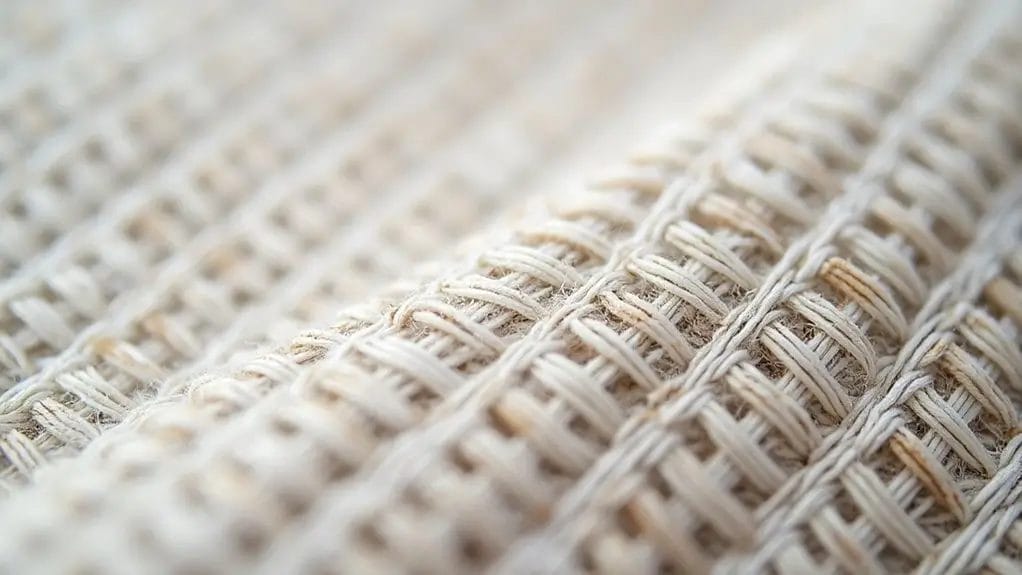

Oxford fabric is a distinctive basket-weave textile produced by interlacing two yarns in a crosswise pattern. This woven fabric's unique construction involves weaving a thicker yarn with a thinner one in both warp and weft directions, creating a slightly elevated texture with visible geometric patterns.

You'll find that oxford fabric's basket weave structure makes it exceptionally durable and versatile. The characteristic pinholes that appear at the intersection of yarns enhance breathability while maintaining structural integrity.

This textile's dimensional stability comes from its balanced weave, where the yarns are distributed evenly throughout the fabric's surface.

How is Oxford Fabric Made?

Oxford fabric emerges from the combination of colored and white yarns, typically utilizing cotton, polyester, or a blend of both materials.

You'll find that manufacturers create this durable fabric by weaving two yarns over one yarn in a basket weave pattern, which produces its distinctive checkerboard texture.

The manufacturing process incorporates a double-yarn warp thread interwoven with a single-yarn weft thread, resulting in the fabric's characteristic strength and slight sheen.

Materials Used in Oxford Fabric

Traditionally manufactured from cotton fibers, Oxford fabric employs a distinctive basket weave construction that interlaces two yarns in the warp with a single yarn in the weft.

While pure cotton remains popular, you'll find modern Oxford fabrics incorporating synthetic materials like polyester and viscose. These synthetic fibers enhance durability and wrinkle resistance while reducing production costs.

Manufacturers often blend cotton with polyester at various ratios (60/40 or 70/30) to combine cotton's breathability with synthetic fiber's strength.

You can also find specialty Oxford fabrics made from premium materials like Egyptian cotton or performance-enhanced synthetic blends.

Weaving Process

The basket weave construction forms the foundation of Oxford fabric's signature texture and appearance.

In this type of woven textile, two or more weft yarns interlace with two or more warp yarns in a prominent and complex weave pattern.

You'll find that this method creates a distinctive checkerboard effect, where the raised yarns make the fabric more durable than plain weaves.

Manufacturers use a tighter basket weave variation in the textile industry to produce finer Oxford cloth, while looser weaves result in heavier fabrics.

The lengthwise yarns are typically dyed, while filling yarns remain white.

Characteristics of Oxford Fabric

You'll find Oxford fabric's defining characteristic in its distinctive basket weave structure, where multiple warp yarns interlace with a single weft yarn to create its signature textural pattern.

The fabric's specialized construction yields exceptional tensile strength and tear resistance, making it particularly suitable for garments that endure frequent wear and laundering.

The material's surface presents a slightly raised, tactile quality that you can feel when running your fingers across its distinctive geometric patterns, while maintaining a crisp, professional appearance.

Weave Structure

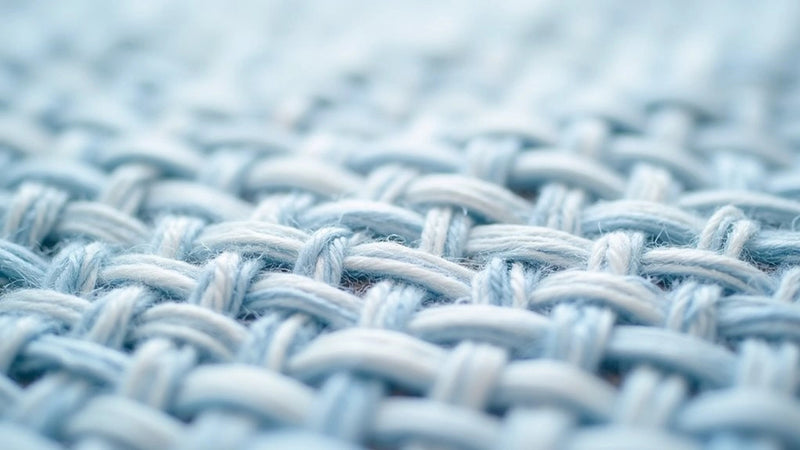

When examining Oxford fabric's weave structure, you'll notice its distinctive basket-weave pattern created by interlacing two warp yarns with a single weft yarn. This woven construction produces small geometric squares with a slightly raised texture.

The fiber used is typically yarn-dyed, meaning individual threads are colored before weaving.

Oxford fabric is made by using a 2x1 basket weave variation, where two fine yarns in the warp direction cross over and under a heavier single weft yarn.

This structure creates the fabric's characteristic piqué appearance and contributes to its durability and breathability.

Durability and Strength

Thanks to its basket-weave construction and tightly interwoven threads, Oxford fabric exhibits exceptional durability characteristics compared to standard plain weaves.

You'll find it's highly resistant to wear and tear, making it ideal for garments that face frequent use and washing.

The fabric's unique structure allows it to withstand abrasion, with heavier variants like 600D Oxford offering superior resistance and durability in demanding applications.

While maintaining its structural integrity, Oxford fabric shows minimal signs of deterioration even after extended use.

This durable fabric's strength-to-weight ratio makes it particularly suitable for both apparel and technical applications.

Texture and Feel

Distinguished by its unique basket weave construction, Oxford fabric presents a slightly raised, textured surface with a characteristic pebbled appearance.

You'll notice it's smooth yet structured, with a thicker hand feel compared to standard cotton weaves. The fabric's finer yarns create a shinier finish on the face side, while maintaining a matte texture underneath.

While it's prone to wrinkle due to its cotton composition, Oxford fabric offers excellent breathability. The level of comfort increases with each wash as the fibers soften, though the distinctive texture remains intact throughout the fabric's lifespan.

Different Types of Oxford Fabric

You'll encounter four primary variations of Oxford fabric in textile manufacturing:

Plain Oxford features a basic 2x1 basket weave.

Pinpoint Oxford utilizes finer yarn counts for increased thread density, and Oxford Nylon incorporates synthetic fibers for enhanced durability.

Royal Oxford stands apart with its distinctive diagonal weave pattern and lustrous appearance achieved through specialized yarn arrangements.

These distinct manufacturing processes yield fabrics with varying textures, weights, and performance characteristics suited to specific end-uses.

Plain Oxford

Plain Oxford represents the most fundamental and widely produced variant of Oxford cloth, characterized by its signature basket-weave construction using a 2:1 thread ratio.

You'll find this regular oxford fabric commonly made from pure cotton, though modern blends exist. The lightweight fabric features a slightly textured surface created by interlacing one thick yarn with two thinner ones.

When you're examining dress shirts made from plain oxford, you'll notice its distinctive matte appearance and superior breathability.

The fabric's durability comes from its balanced construction, while maintaining a softer hand than pinpoint or royal oxford variants.

Pinpoint Oxford

Moving from regular Oxford's basic weave, Pinpoint Oxford employs a tighter construction using finer yarns in its 2:1 thread ratio.

You'll notice this type of fabric creates a smoother, more refined surface than standard oxford textiles while maintaining durability.

In oxford shirts, Pinpoint's characteristics include enhanced wrinkle resistance and a more formal appearance.

The fabric's versatility makes it suitable for both business and smart-casual settings.

You'll find this oxford fabric used extensively in dress shirts where you need the perfect balance between professional polish and everyday comfort.

The tighter weave also results in better temperature regulation and shape retention.

Oxford Nylon

While traditional Oxford fabric relies on cotton, Oxford nylon introduces synthetic fibers into the classic 2:1 basket weave construction. You'll find this durable material measured in denier units, indicating the fiber thickness and strength.

Manufacturers often apply PU (polyurethane) coatings to enhance its water-resistant properties.

Oxford nylon's synthetic composition makes it ideal for outdoor gear where waterproof performance is essential. You'll commonly see it used in backpacks, tents, and weather-resistant clothing.

The fabric's tight weave and synthetic fibers create a robust barrier against moisture while maintaining breathability, making it a go-to choice for technical outdoor equipment.

Royal Oxford

Royal Oxford stands apart from standard Oxford nylon through its sophisticated 4x2 basketweave construction.

This premium oxford fabric depends on an intricate weaving pattern that creates a distinctly lustrous surface with subtle diagonal lines. You'll find royal oxford fabric extensively used in high-end dress shirts and formal apparel.

- The fabric's unique construction uses fine, two-ply yarns in both warp and weft directions.

- Its smoother texture and higher thread count deliver enhanced durability and drape.

- The material's refined appearance can withstand repeated laundering while maintaining its characteristic sheen.

Royal oxford's elegance makes it suitable for business and ceremonial wear where sophistication matters.

Uses of Oxford Fabric

You'll find Oxford fabric's most prominent use in garment manufacturing, where it's crafted into dress shirts, casual button-downs, and uniform apparel.

The fabric's distinctive basket weave construction makes it ideal for home textiles like curtains, tablecloths, and upholstery, offering both durability and aesthetic appeal.

In outdoor applications, manufacturers utilize Oxford's water-resistant properties and tear strength to produce tents, backpacks, and protective gear.

Oxford Fabric in Clothing

Oxford fabric serves as a cornerstone material in modern clothing manufacturing, particularly excelling in the production of dress shirts, casual button-downs, and sportswear.

Today's fabric is commonly used with both cotton and synthetic fibers such as polyester. You'll find it's a practical choice for everyday wear due to its durability and versatility.

- Polyester oxford blends offer enhanced wrinkle resistance and moisture-wicking properties

- Cotton oxford variations provide superior breathability and a more traditional appearance

- Modern oxford weaves are suitable for a wide range of garments, from formal attire to athletic wear

Oxford Fabric in Home Textiles

The versatility of Oxford fabric extends beyond apparel into home textiles, where it's frequently utilized in upholstery, curtains, and decorative pillowcases.

You'll find this polyester fabric coated with polyurethane for enhanced durability in high-traffic areas of your home. Its basket weave construction makes it resistant to wear and tear, perfect for furniture covers and throw pillows.

Oxford fabric's wide range of applications in home textiles makes it a popular choice for interior designers.

You can select from various weights and finishes to match your specific needs, from lightweight curtains to heavy-duty upholstery material.

Oxford Fabric in Tents and Outdoor Gear

Modern outdoor enthusiasts rely on polyurethane-coated Oxford fabric for its exceptional water resistance and durability in tents, backpacks, and camping gear.

The fabric has become essential in outdoor equipment manufacturing, with 600D Oxford fabric leading the way in heavy-duty applications.

- PU-coated Oxford's tight weave and synthetic coating can withstand harsh weather conditions, UV exposure, and repeated use.

- 420D variations offer lighter weight options ideal for outdoor applications like daypacks and lightweight tent components.

- Different types of Oxford fabric provide varying levels of water resistance, with heavier deniers offering superior protection against moisture and abrasion.

Frequently Asked Questions

Can Oxford Fabric Shrink After Washing?

Yes, you'll find that Oxford fabric can shrink up to 3-5% during washing, particularly in hot water. You'll need to pre-wash it or use cold water to minimize shrinkage potential.

Is Oxford Fabric Suitable for Hot Weather Climates?

You'll find Oxford fabric suitable for warm weather due to its breathable basket weave construction. Its cotton yarns allow air circulation, while the fabric's crisp texture keeps it slightly lifted from your skin.

How Long Does Oxford Fabric Typically Last With Regular Wear?

You'll get 2-3 years of regular wear from quality Oxford fabric, as its basket weave construction and doubled yarns provide exceptional durability, though longevity depends on washing frequency and care practices.

Does Oxford Fabric Require Special Care When Ironing?

You'll need to iron Oxford fabric while damp, using medium heat and the fabric's reverse side. Don't skip the starch during laundering, as it'll help maintain the characteristic basket weave texture.

Can Oxford Fabric Be Used for Outdoor Furniture Upholstery?

You'll need treated or coated Oxford fabric for outdoor furniture, as standard Oxford isn't weather-resistant. Choose polyester Oxford with UV protection and water-repellent finish for ideal outdoor performance.

Conclusion

You'll find Oxford fabric to be an engineering marvel, combining structural durability with versatile applications. Its distinctive basket weave construction, utilizing differential yarn thicknesses, creates a textile that's both robust and adaptable. Whether you're selecting Plain Oxford for breathable shirting or water-resistant Oxford Nylon for technical gear, you're working with a material that's proven its manufacturing versatility across multiple industries and applications.

0 comments